Rigging and material handling are essential tasks in many industries. Ensuring these tasks are performed safely is paramount to preventing accidents, injuries, and property damage.

A well-structured rigging material handling safety program template can help organizations establish and implement comprehensive safety protocols. This article provides an overview of the key elements to include in such a template and guidance on how to develop an effective rigging and material handling safety program.

Program Scope and Objectives

The first step in developing a rigging material handling safety program template is to establish its scope and objectives. This involves identifying the specific activities, operations, and equipment covered by the program. The objectives should clearly outline the desired safety outcomes, such as reducing accidents and incidents, improving compliance with applicable regulations, and fostering a culture of safety.

Once the scope and objectives are defined, organizations should develop detailed procedures and protocols for each aspect of rigging and material handling operations. These procedures should address potential hazards, establish safe work practices, and outline the responsibilities of employees at all levels.

Hazard Identification and Risk Assessment

Hazard identification and risk assessment are crucial components of a rigging material handling safety program template. Organizations must conduct thorough risk assessments to identify potential hazards and evaluate their likelihood and severity of occurrence. Common hazards include equipment failures, improper training, and environmental factors.

Based on the risk assessments, organizations should establish appropriate control measures to mitigate identified hazards. These measures may include engineering controls, such as guarding and automated systems, administrative controls, such as training and work permits, and personal protective equipment, such as gloves and safety glasses.

Training and Competence

Training and competence are critical elements of any rigging material handling safety program template. Ensuring that employees have the necessary knowledge, skills, and qualifications to perform rigging and material handling tasks safely is essential. Organizations should develop comprehensive training programs that address the specific requirements of their operations.

Training should cover topics such as hazard identification, safe work practices, and emergency procedures. Employees should be evaluated regularly to ensure their competence and adherence to safety protocols. Refresher training should be provided periodically to reinforce safety knowledge and update employees on any changes in regulations or company policies.

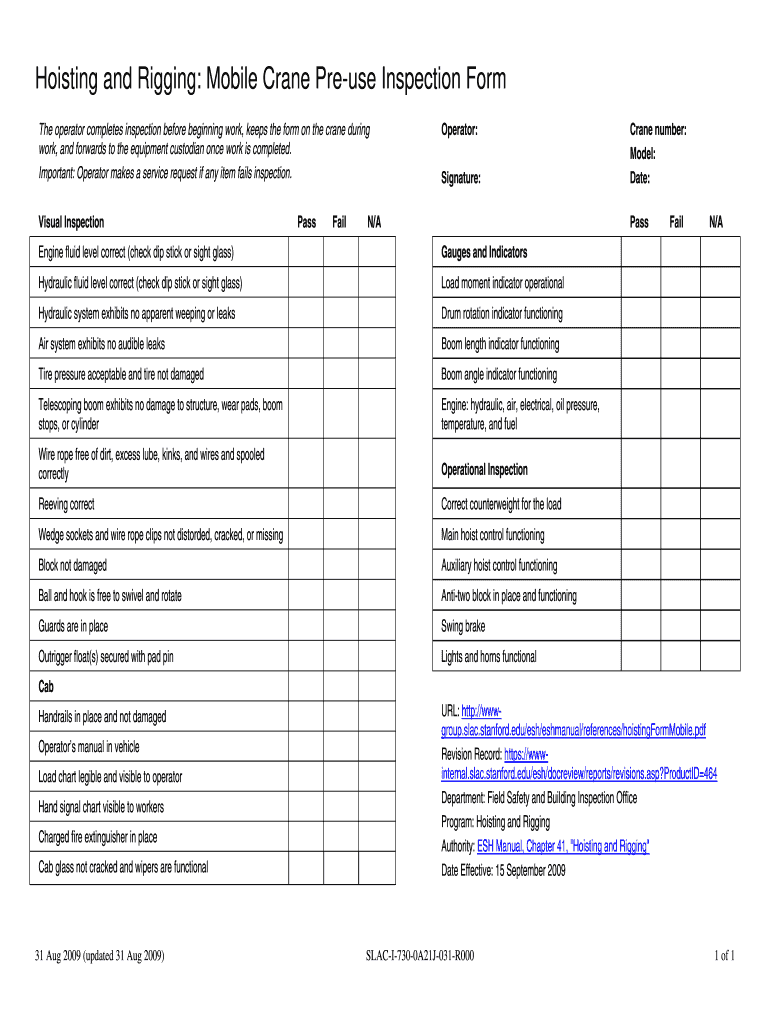

Inspection and Maintenance

Regular inspection and maintenance of rigging and material handling equipment are essential to ensure its safe operation. Organizations should establish inspection and maintenance schedules that are based on the manufacturer’s recommendations, industry best practices, and the specific usage of the equipment.

Inspections should be conducted by trained and qualified personnel who can identify potential defects or damage. Maintenance should be performed according to the manufacturer’s specifications and industry standards. Records of all inspections and maintenance should be maintained and reviewed regularly to ensure compliance and identify any patterns or trends that may indicate potential safety issues.

By following these guidelines and incorporating these key elements into a rigging material handling safety program template, organizations can create a comprehensive and effective safety program that helps to protect their employees, prevent accidents, and ensure compliance with applicable regulations.