Creating an OSHA-compliant fall protection program is essential for ensuring the safety of workers at height. This comprehensive guide will provide you with a step-by-step approach to develop an effective fall protection program using the OSHA fall protection program template. Whether you are a safety professional or an employer, this article will equip you with the knowledge and tools to implement a robust fall protection system.

An OSHA fall protection program template serves as a structured framework to help employers establish and maintain a comprehensive fall protection program that complies with OSHA standards. By following the guidelines provided in the template, employers can assess fall hazards, develop control measures, and establish procedures to prevent falls. This template ensures that all necessary components of a fall protection program are addressed, including hazard identification, training, equipment inspection, and emergency response.

Developing a Comprehensive Fall Protection Program

The OSHA fall protection program template guides employers through the following key steps:

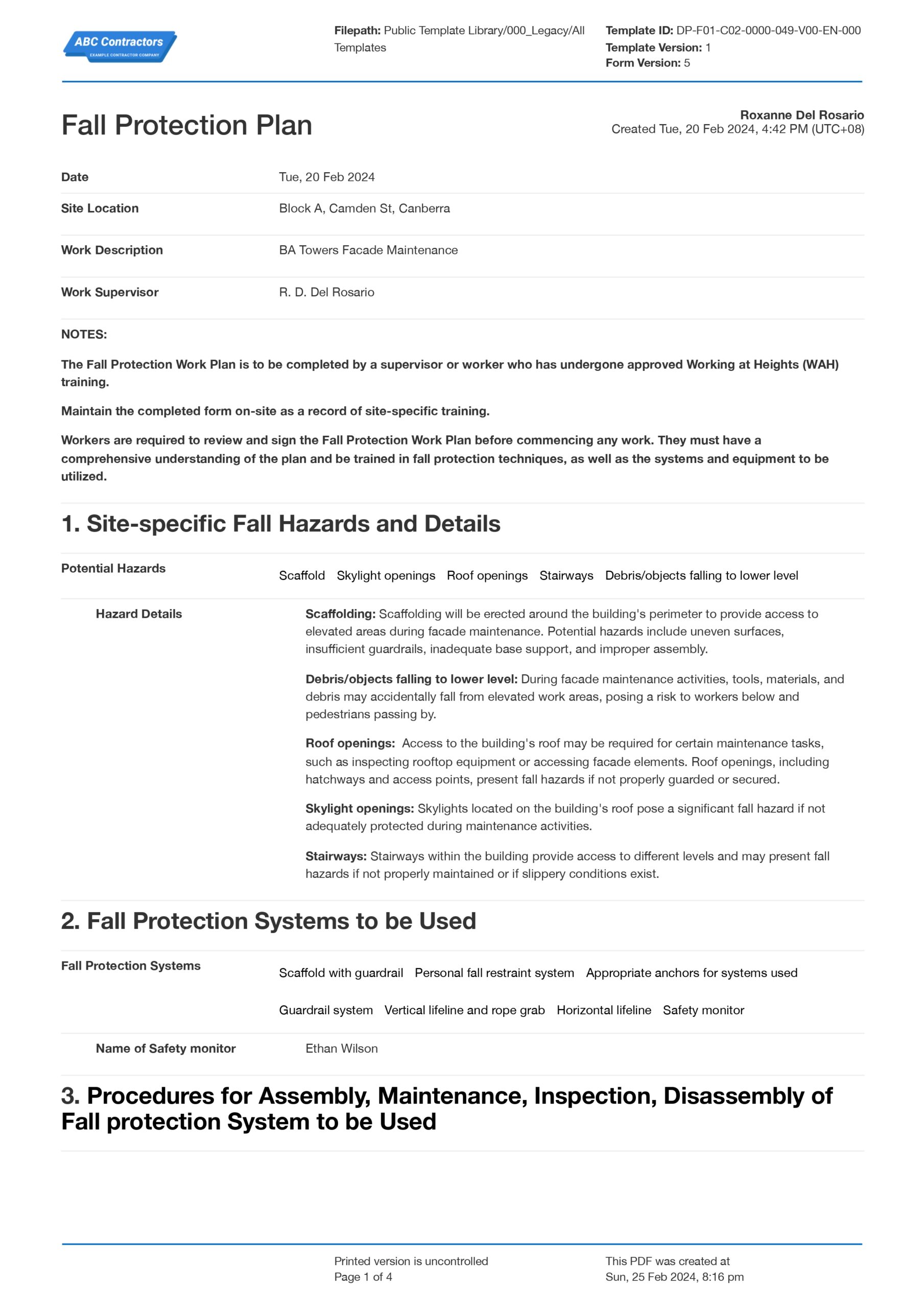

1. Hazard Identification: Conduct thorough worksite assessments to identify potential fall hazards, including heights, roof openings, and elevated work surfaces. Evaluate the frequency and duration of work activities at these heights to determine the risk level.

2. Hazard Analysis: Analyze identified hazards to determine the likelihood and severity of potential falls. Consider factors such as equipment used, work procedures, environmental conditions, and employee training. This assessment will help you prioritize control measures.

3. Control Measures: Implement appropriate control measures to prevent or eliminate fall hazards. This includes using collective fall protection systems (such as guardrails and safety nets), personal fall arrest systems (such as harnesses and lifelines), and administrative controls (such as worksite access restrictions and training).

4. Training: Provide comprehensive training to employees on fall protection procedures, equipment use, and hazard recognition. Ensure that training is job-specific and conducted by qualified instructors. Document and maintain training records for each employee.

Program Implementation and Maintenance

5. Equipment Inspection and Maintenance: Establish a regular schedule for inspecting and maintaining fall protection equipment. This includes visual inspections, functionality tests, and repairs or replacements as needed. Ensure that all equipment meets OSHA standards and is used correctly.

6. Program Evaluation and Review: Regularly evaluate the effectiveness of the fall protection program and identify areas for improvement. Conduct periodic inspections, monitor fall incidents, and seek feedback from employees to ensure the program remains effective.

7. Emergency Response Plan: Develop an emergency response plan that includes procedures for responding to fall incidents. This plan should outline communication protocols, rescue procedures, and medical treatment arrangements.

8. Recordkeeping: Maintain accurate records of fall protection training, equipment inspections, and fall incidents. These records should be used to demonstrate compliance with OSHA standards and to track the effectiveness of the program.

By following the OSHA fall protection program template and implementing these comprehensive measures, employers can effectively prevent falls, protect employee safety, and maintain compliance with OSHA regulations.

Remember, fall protection is an ongoing process that requires continuous monitoring, evaluation, and improvement. By actively engaging in fall prevention measures and using the OSHA fall protection program template as a guide, you can create a work environment where employees are safe from the hazards of working at height.