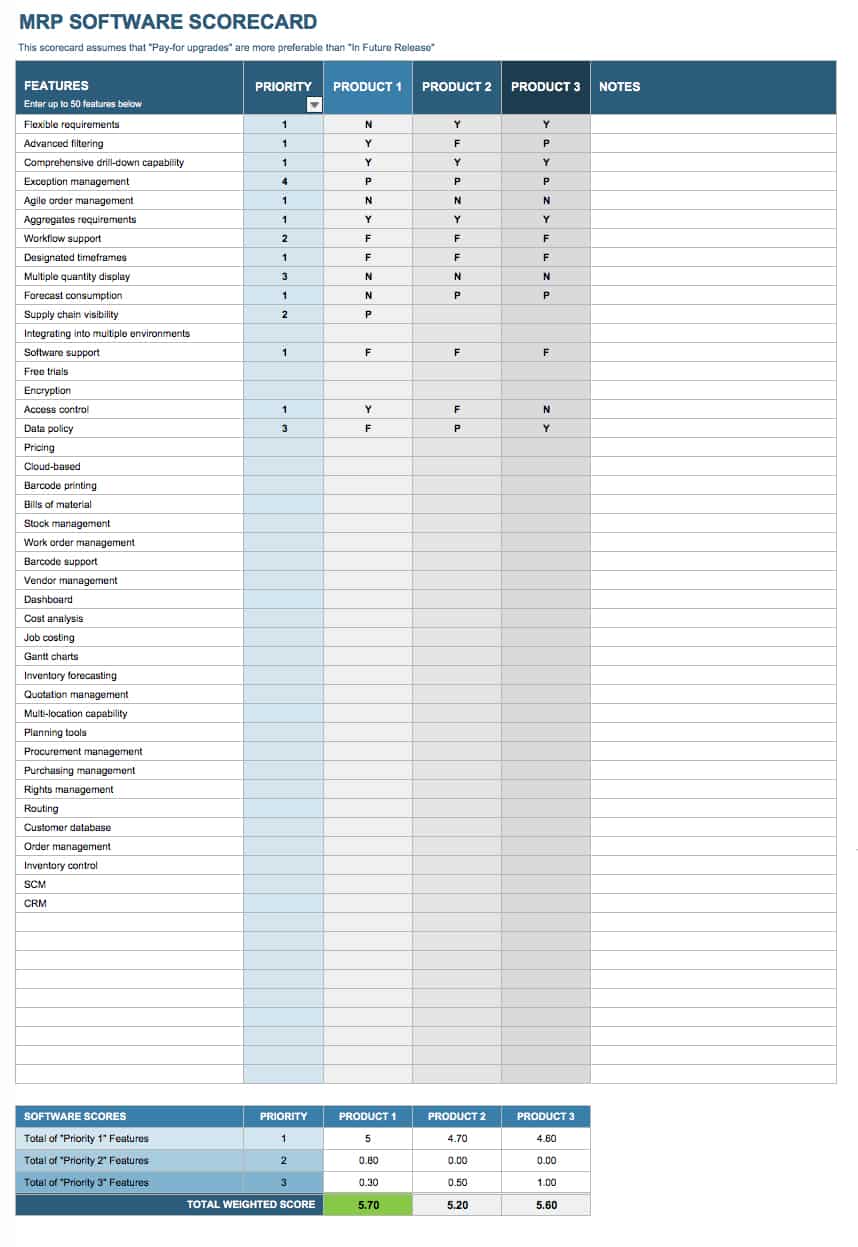

Material requirements planning (MRP) is a critical process for any manufacturing business. It helps to ensure that the right materials are available at the right time and in the right quantity to meet production demands. A well-structured MRP template can streamline this process and make it more efficient.

In this article, we will provide you with a comprehensive MRP template that you can use to improve your material planning process. We will also discuss the key elements of an MRP template and how to use it effectively.

MRP Template Components

An effective MRP template should include the following components:

- Product structure: This defines the hierarchical relationship between the finished product and its component parts.

- Bill of materials (BOM): This lists all the materials and components required to produce the finished product, along with their quantities and specifications.

- Production schedule: This outlines the planned production schedule for the finished product, including the start and end dates for each production run.

- Inventory data: This provides information on the current inventory levels of all materials and components used in the production process.

- Lead times: This specifies the time it takes to procure each material or component.

Once you have gathered all of the necessary information, you can begin to create your MRP template. There are a number of software programs that can help you to automate this process.

Using an MRP Template

Once you have created your MRP template, you can begin to use it to plan your material requirements. To do this, you will need to:

- Enter your production schedule into the template.

- Enter your inventory data into the template.

- Enter your lead times into the template.

- The template will then calculate the materials and components that you need to order and the dates that you need to order them.

- You can then use this information to create purchase orders and schedule deliveries.

By using an MRP template, you can streamline your material planning process and ensure that you have the right materials on hand to meet your production demands. This can help you to improve your efficiency and profitability.

Conclusion

An MRP template is a valuable tool for any manufacturing business. It can help you to streamline your material planning process, reduce inventory costs, and improve your customer service. If you are not already using an MRP template, we encourage you to implement one today.

We hope this article has provided you with the information you need to create and use an MRP template. If you have any questions, please do not hesitate to contact us.