An OSHA lockout tagout program template is a document that provides a framework for creating a comprehensive lockout tagout program. This program is designed to prevent the unintentional release of hazardous energy during servicing and maintenance activities. The template includes essential elements such as procedures for identifying and isolating energy sources, using lockout devices, and training employees.

Having a well-developed OSHA lockout tagout program is crucial for ensuring the safety of workers who perform hazardous tasks. By following the guidelines outlined in the template, organizations can establish a system that effectively controls energy sources during maintenance and repairs, reducing the risk of accidents and injuries.

Developing an OSHA Lockout Tagout Program

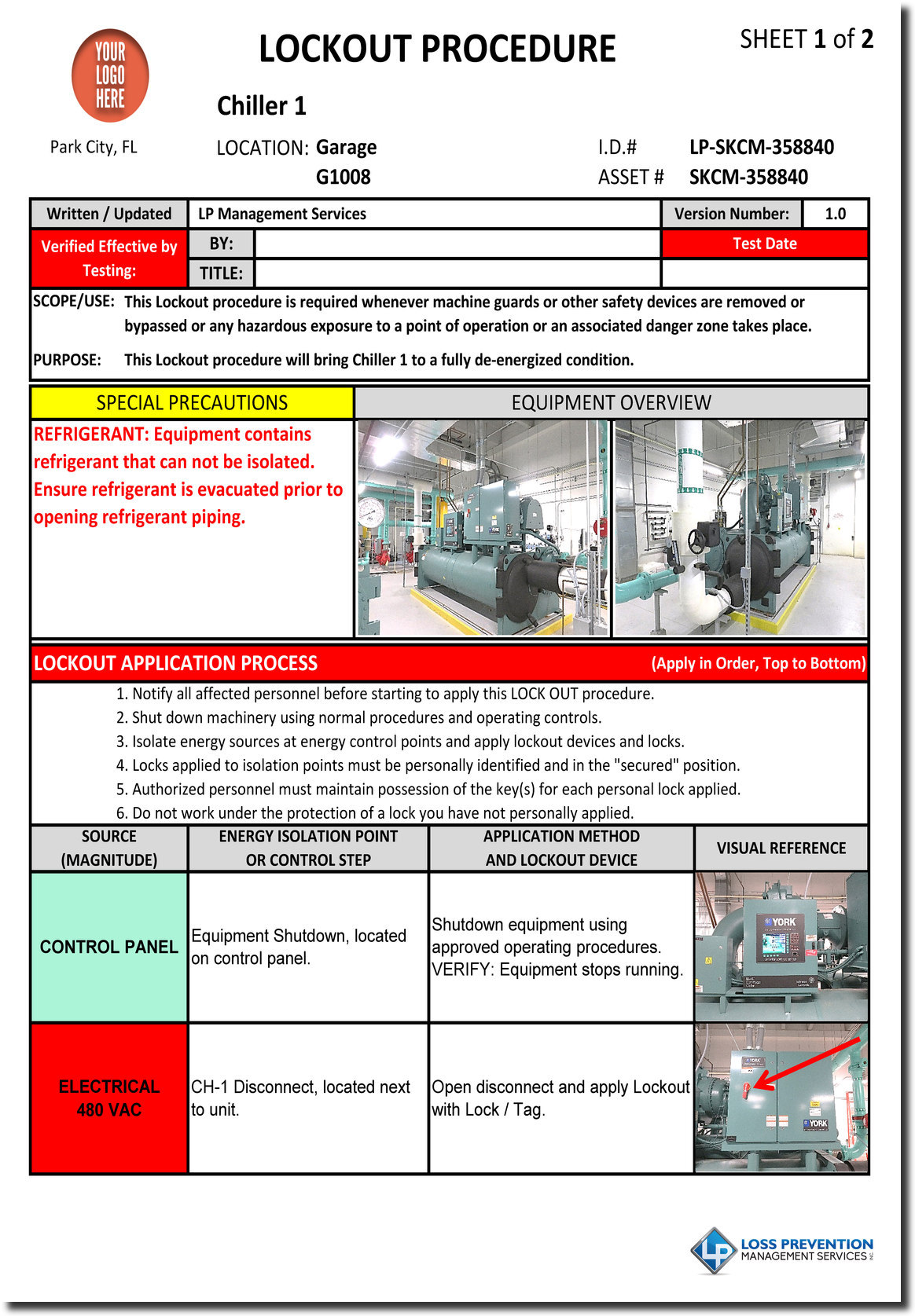

The OSHA lockout tagout program template outlines the steps and considerations involved in developing a comprehensive program. It begins by identifying the scope of the program, which includes determining the types of machinery and equipment that require lockout tagout procedures. The template also emphasizes the need for training employees on the program’s requirements and best practices.

Another crucial aspect of the program is establishing clear and detailed lockout procedures. These procedures should specify the steps to be taken before performing hazardous tasks, including isolating energy sources, affixing lockout devices, and verifying the effectiveness of the lockout. The template provides guidance on developing lockout procedures that are specific to the equipment and processes used in the workplace.

Regular inspection and auditing are essential for ensuring the effectiveness of the lockout tagout program. The template includes guidelines for conducting inspections and audits, which involve verifying the implementation of lockout procedures, checking the condition of lockout devices, and identifying any areas for improvement.

Finally, the template emphasizes the importance of recordkeeping and documentation. Maintaining accurate records of lockout tagout procedures, inspections, and training provides evidence of compliance with OSHA regulations and facilitates continuous improvement efforts.

Additional Considerations for an Effective Lockout Tagout Program

In addition to the elements outlined in the OSHA lockout tagout program template, there are several additional considerations for organizations to ensure the effectiveness of their program. One important aspect is involving employees in the development and implementation of the program, as their knowledge and experience can contribute to its success.

Another crucial factor is ongoing training and communication. It is essential to provide regular training to employees on lockout tagout procedures, best practices, and any updates to the program. Effective communication channels should be established to ensure that employees are aware of the program’s requirements and can report any concerns or suggestions for improvement.

Furthermore, organizations should consider using lockout tagout devices that meet OSHA standards and are suitable for the specific equipment and processes involved. The use of standardized lockout devices helps prevent confusion and ensures that all employees are using the correct devices consistently.

Regular review and evaluation of the lockout tagout program are crucial for maintaining its effectiveness. Organizations should conduct periodic reviews to identify areas for improvement, address any issues or concerns raised by employees, and ensure that the program remains aligned with OSHA regulations and industry best practices.

By following the guidelines outlined in the OSHA lockout tagout program template and considering the additional aspects discussed in this article, organizations can develop comprehensive and effective lockout tagout programs that protect the safety of their workers and prevent the unintentional release of hazardous energy during maintenance and repair activities.